High Quality Butterfly Valve for Auto Parts

- Certificate:

- ISO 9001:2008

- HS Code:

- 7616991090

- Port:

- Qingdao

Basic Info

Model No.: 159

Product Description

High Quality Butterfly valve for Auto Parts

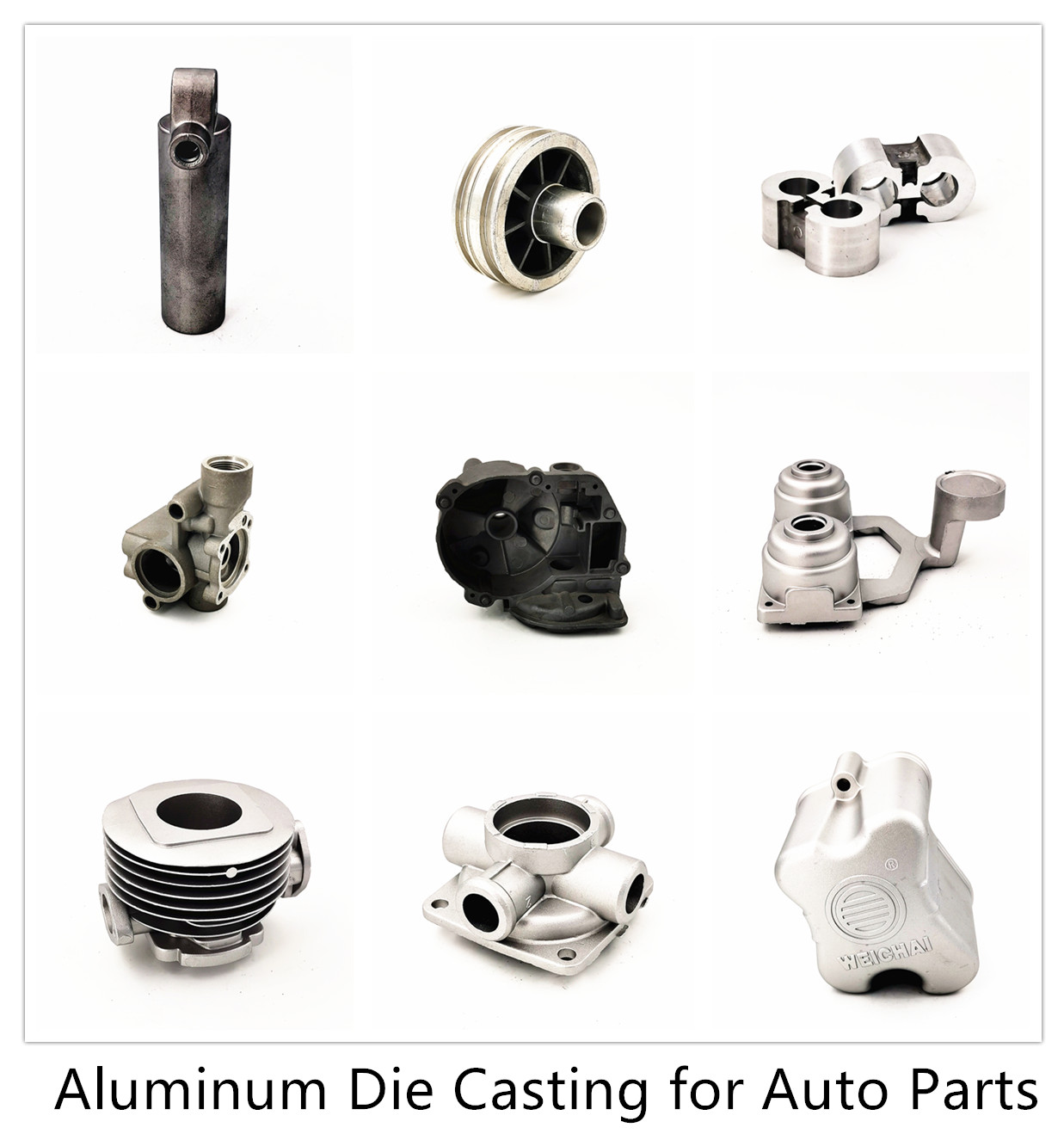

The Company jointly manufactures and exports a variety of Casting Products for architectural, automotive, mechanical parts.

We export to more than 20 countries on 6 continents and have been doing so for more than 10 years. Our main product line includes precision casting, die casting, welding and CNC machining. Materials vary from aluminum, zinc alloy, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

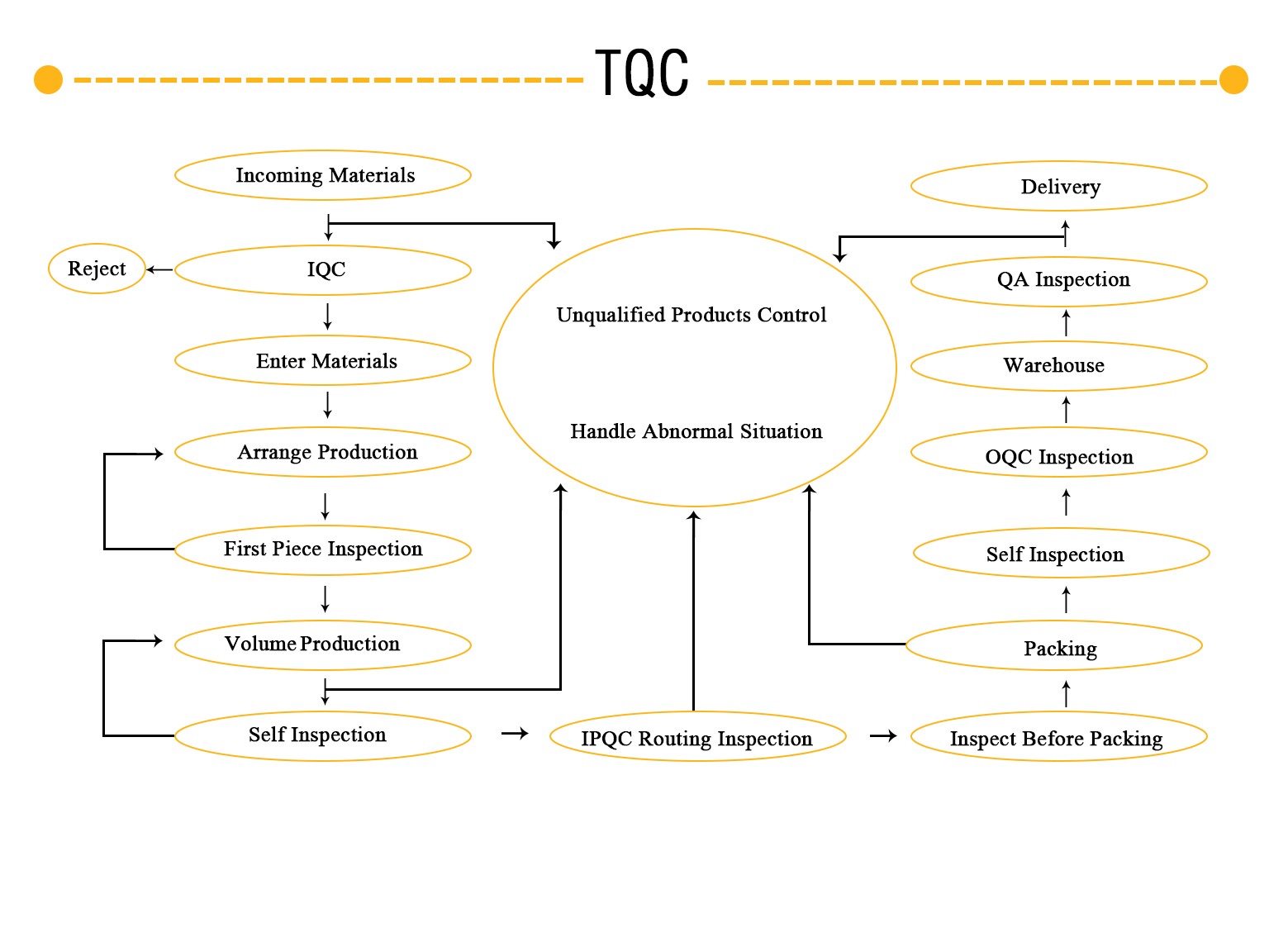

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines. We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment and X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.

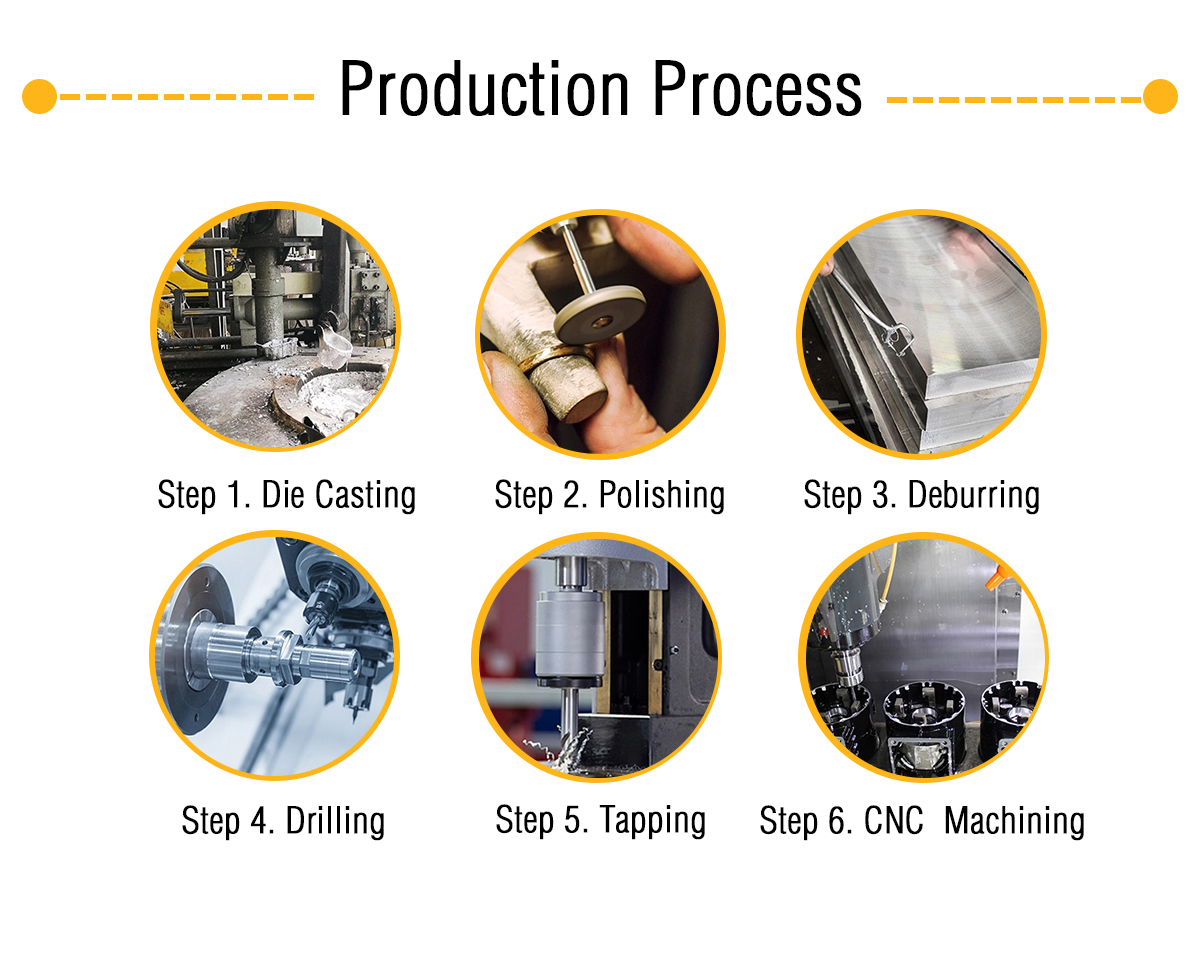

| Process: | 1) Die Casting / Profile Extrusion 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading 3) Surface Treating 4) Inspection and Packaging |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. 2) Aluminum Alloys Profile Extrusion: 6061, 6063 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. |

| Surface Treatment: | Polishing Shot Blasting Sandblasting Powder Coating Anodizing Chrome Plating Passivation E-coating T-coating etc. |

| Tolerance: | +/-0.05mm |

| Weight Per Unit: | 0.01-50KG |

| Order Lead Time: | 20-45 Days (According the Quantity and Complexity of the Product |

The Company jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts.

We export to more than 20 countries on 6 continents and have been doing so for more than 10 years. Our main product line includes precision casting, die casting, welding and CNC machining. Materials vary from aluminum, zinc alloy, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines. We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment and X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.

| Q1.What is the specific fabrication process ? |

| Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale Service. |

| Q2.What's the production time for new molds and mass production? |

| 10-20 days to make the new moulds, mass production takes around 15 days,can process urgently if need |

| Q3.Can you send me samples ? |

| Yes, Samples are for free, and freight is on your side. |

| Q4.How long is the lifetime ? |

| Powder coating for 18-20 years outdoor. |

| Q5.What is the payment terms ? |

| T/T: 30% deposit, the balance will be paid before delivery; |

Product Categories : Aluminum Die Casting > Auto Aluminum Die Parts